Tooling & Stamping

We manufacture complex and sophisticated sheet metal forming tools and stamping parts, which are used in the highly demanding automotive industry.

Employees

Square meters

Machines

Years of business

ABOUT US

iFORM d.o.o.

The company based in Bosnia and Herzegovina was founded in 2010. It is a top independent toolmaker and manufacturer of high volumes stamping parts in the automotive industry. We produce complex and sophisticated metal sheet reshaping tools, which find their application in highly demanding automotive industry. Thanks to the high performance machines we use, our company produces between 500 and 700 tons of steel tools annually. On our series presses, we stamp more than 5 000 tons of metal sheets annually. Our primary goal is to provide our customers and employees with reliability, security and a positive partnership atmosphere. That is why we are extremely proud of our team that currently counts more than 200 members as well as our trusted customers. The company is very close to the main customers (OEMs and Tier 1 suppliers) in Germany, Austria and Hungary.

Tons of steel

Tons of metal sheets

Tools per Year

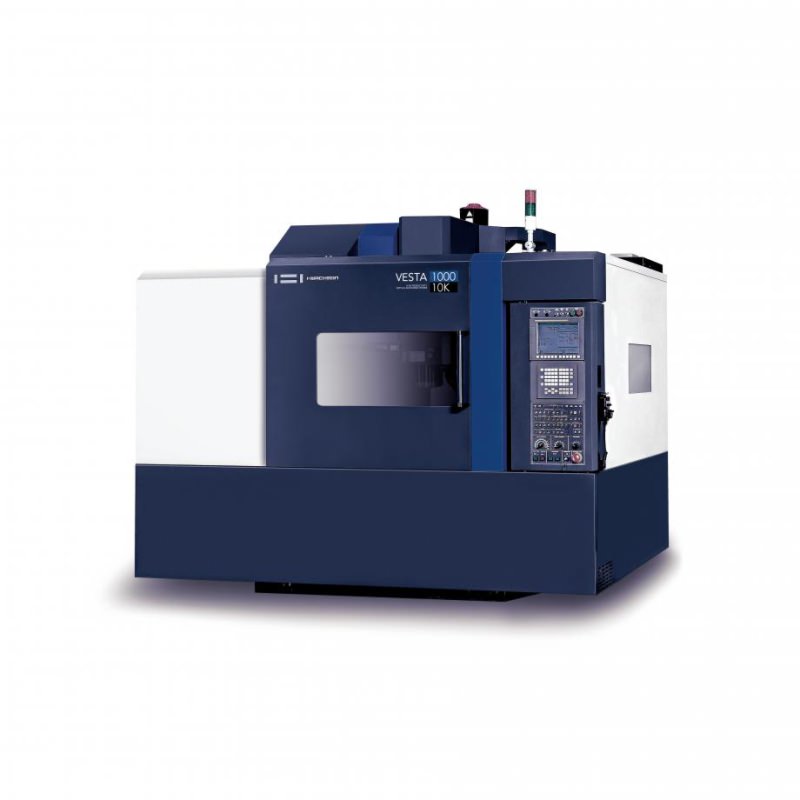

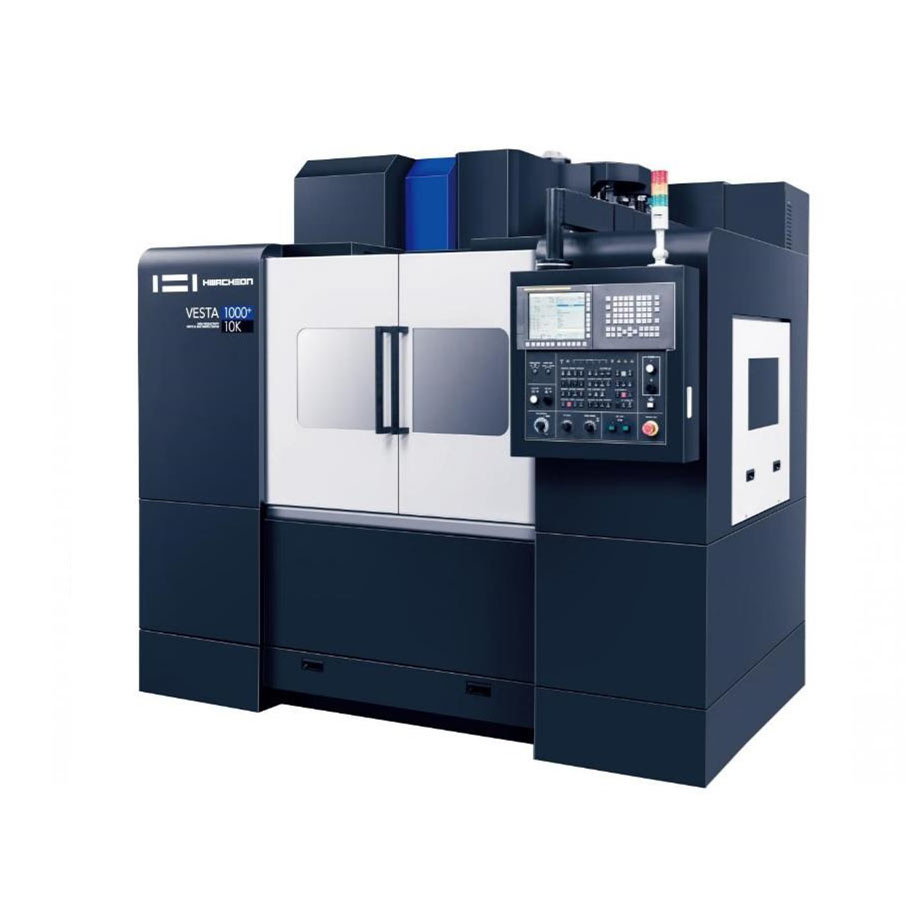

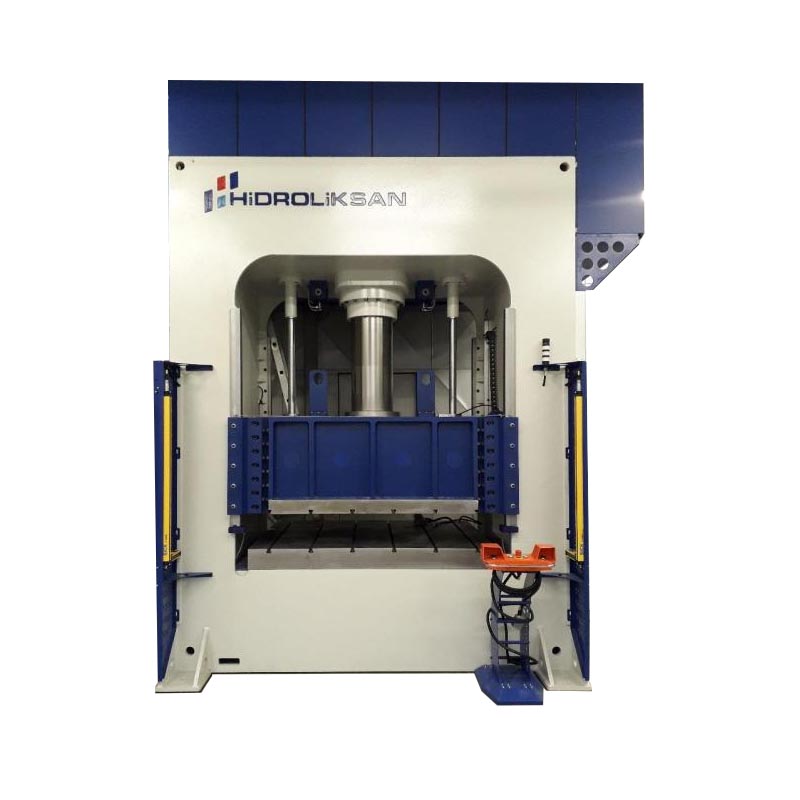

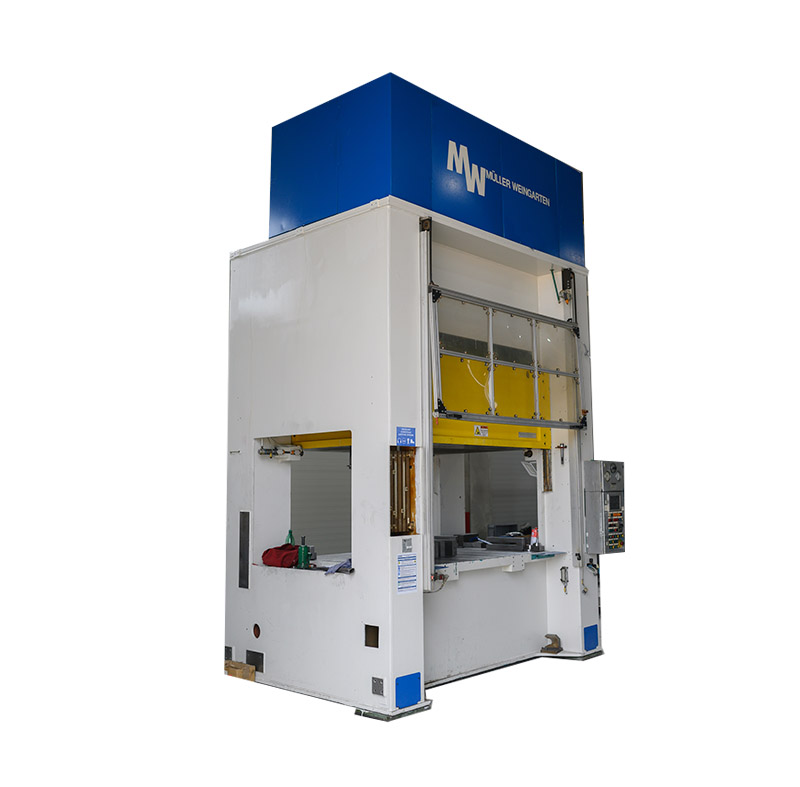

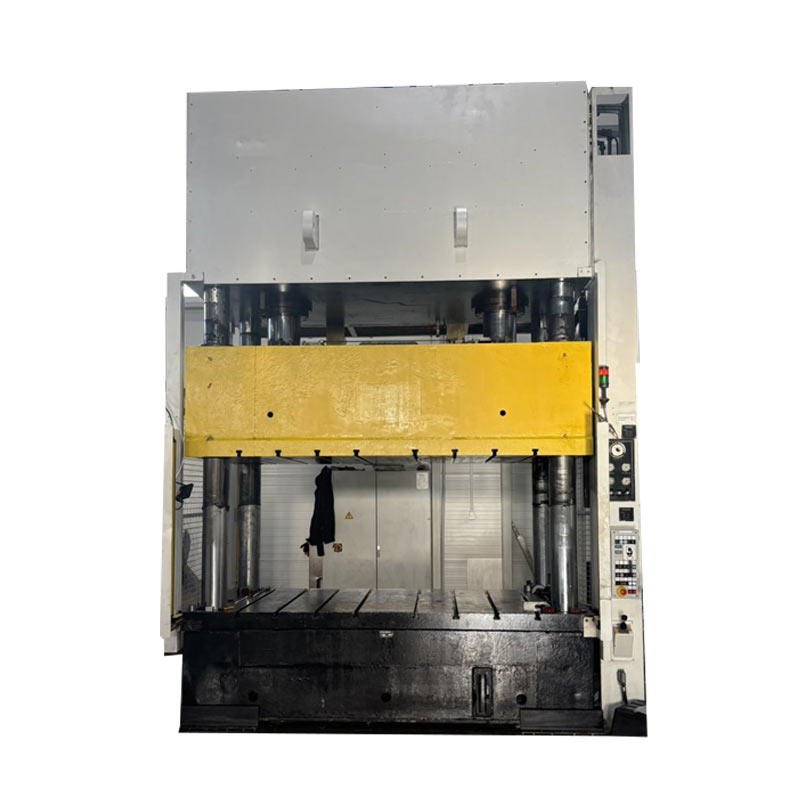

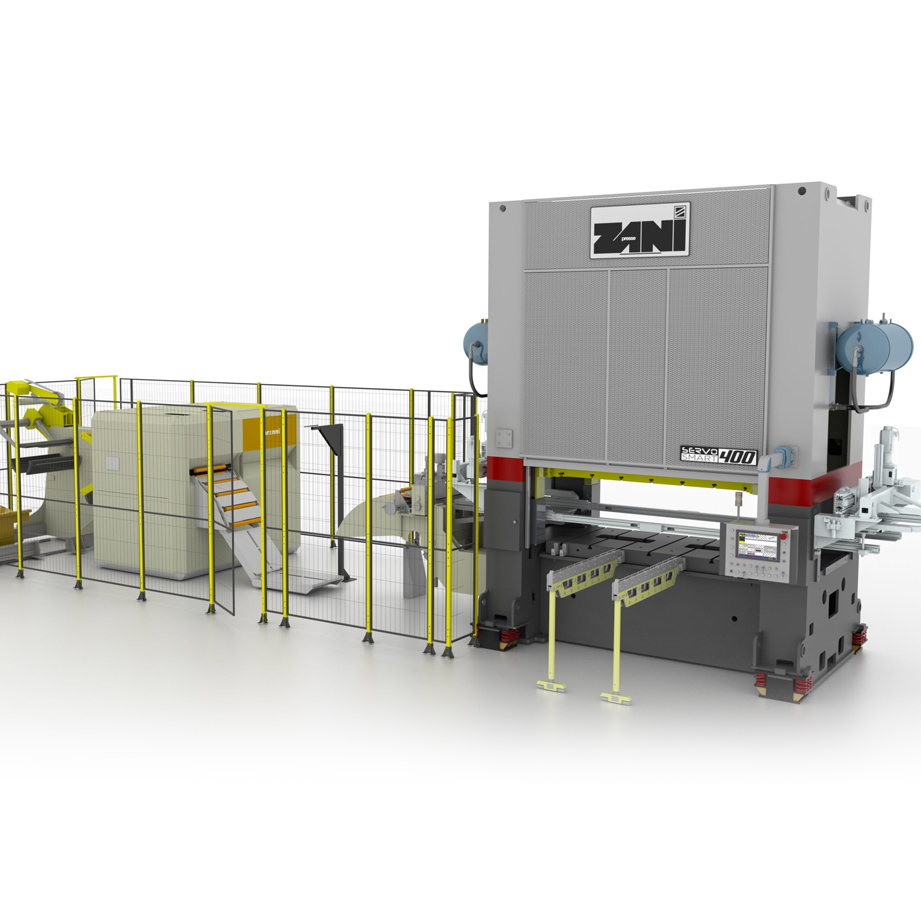

Machine Inventory

Our machine park currently has 30+ high-tech machines that help us optimize our production processes, which is why our final product has extremely high-quality characteristics.

Our products power brands

We care about QUALITY.

Nothing speaks louder of our quality than our satisfied customers

Contact

Phone: +387 (0)39 706 566

Fax: +387 (0)39 719 316

Email: info@iform-tools.com

Industrijska zona Knešpolje, 88220 Široki Brijeg BiH

MON-FRI 08:00 – 16:30

VAT NUMBER: 272385300004 | ID NUMBER: 4272385300004

iFORM LIVING GREEN

At iFORM we are committed to sustainable manufacturing practices and minimizing our environmental impact. We have implemented several initiatives to achieve this goal, including the use of renewable energy sources in our production processes, such as solar and wind power. Our facilities are designed to be energy-efficient, and we strive to reduce waste and optimize resource use. In addition, we continuously review and improve our processes to minimize our carbon footprint and contribute to a cleaner, greener future.

For this purpose, an ESG strategy was created, and in order to transparently report to our partners and the general public about the sustainable practices we implement, we regularly prepare ESG reports. Development and implementation are co-financed with the help of the Environmental Protection Fund of the Federation of Bosnia and Herzegovina

Job at iFORM

You are Looking for a job? Check our positions.